Bac Pro MSPC

BUT GIM

BUT GMP

Engineering Program

About the Author:

Franck JULLIEN & Pierre-Alain BARRY

Enseignant - SII ingénierie mécanique

IUT de Chambéry

Franck JULLIEN et Pierre-Alain BARRY interviennent sur les compétences de conception de packaging et d’industrialisation des solutions d’emballage ou de conditionnement. Ils utilisent les cobots avec leurs étudiants par exemple pour réaliser des opérations de « pick and place » ou de simulation de palettisation.

Required Materials

Niryo Materials:

Other Materials: RoboDK

📋 Project Overview

🔎 Summary

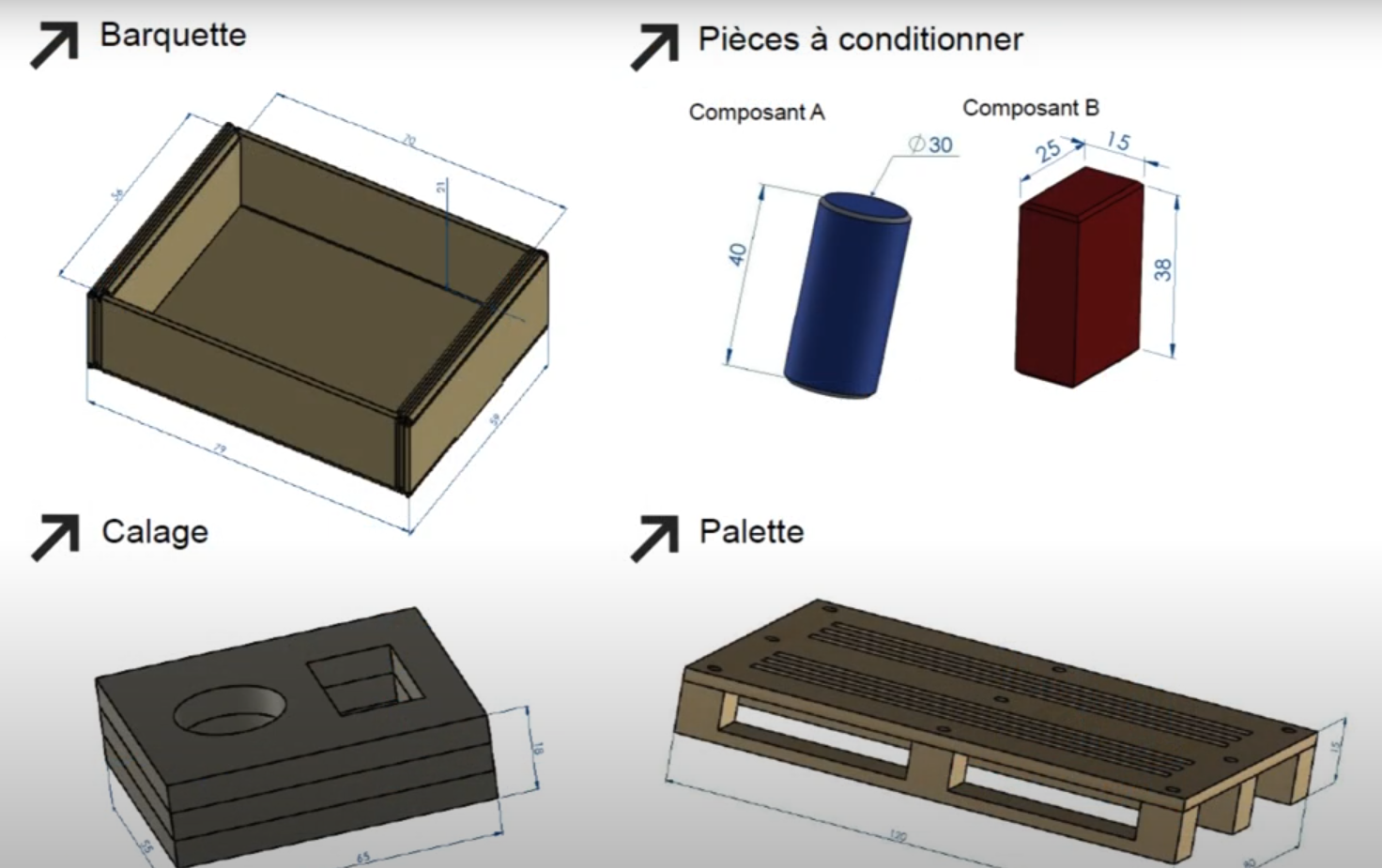

The project: build an automated packaging line for two types of components into corrugated cardboard trays with blister packs, and palletize them.

📝 Full Project Instructions

The project: build an automated packaging line for two types of components into corrugated cardboard trays with blister packs, and palletize them.

Required equipment:

- 3x Niryo robots (NED2 or here 1x Niryo One and 2x NED2)

- 2x conveyors

- 2x customizable grippers

- 1x vacuum pump

- Additional parts:

Part 1: Workstation design and 3D modeling

For station 1:

- Suction cup holder

- Spacer/positioning magazine

- Feeder ramp

For station 2:

- Feeder ramp

- Custom jaws (to be mounted on the customizable gripper)

For station 3:

- Custom jaws (to be mounted on the customizable gripper)

- AGV support (for pallet storage)

Part 2: Digital twin modeling and simulation

Use the simulation software RoboDK to simulate stations 1, 2 and 3 and to break down the operation sequences.

Part 3: Building the robotic cell

Programming of each robot's sequence on NiryoStudio, with Blockly.

Install the three workstations to create the production line:

- Station 1: pick up trays and insert positioning spacers

- Station 2: place the components to be packaged into the trays, then start the conveyor

- Station 3: pick up the filled tray and place it on the pallet. When two trays have been placed on the pallet, activate the conveyor and retrieve a new empty pallet.

The three workstations are synchronized using their input and output signals.

📎 Attached Files